Iron is such an important metal that the change in its price affects many sectors. That’s why it stands out as the most important element in the world. Iron, which is used in a wide range of areas, is an indispensable metal for every sector. Many different features are used to suit the purpose.

Iron Properties

Iron ranks 4th among the most abundant elements in nature. Offering a low cost opportunity also puts it one step ahead in terms of usage. Iron, which has been used in many different areas from ancient times to the present day, offers important privileges with its durability and conductivity as well as its easily shaped structure. The element iron, whose symbol is Fe, is the most abundant metal found free in nature.

The element Iron, which is also of great importance for the human body, has the potential to be used in a much wider area with the addition of carbon in steel and casting production. Its soft structure allows it to be easily shaped over high heat. Although it is an active metal, it offers the ability to combine with many different active nonmetals. In addition to being retrofittable, one of its most important features is that it conducts electricity well.

Briquette Iron (HBI)

Hot Briquetted Iron (HBI) is a premium form of DRI that is compressed during compression at a temperature greater than 650°C and has a density of more than 5,000 kilograms per cubic meter (5,000 kg/m3).

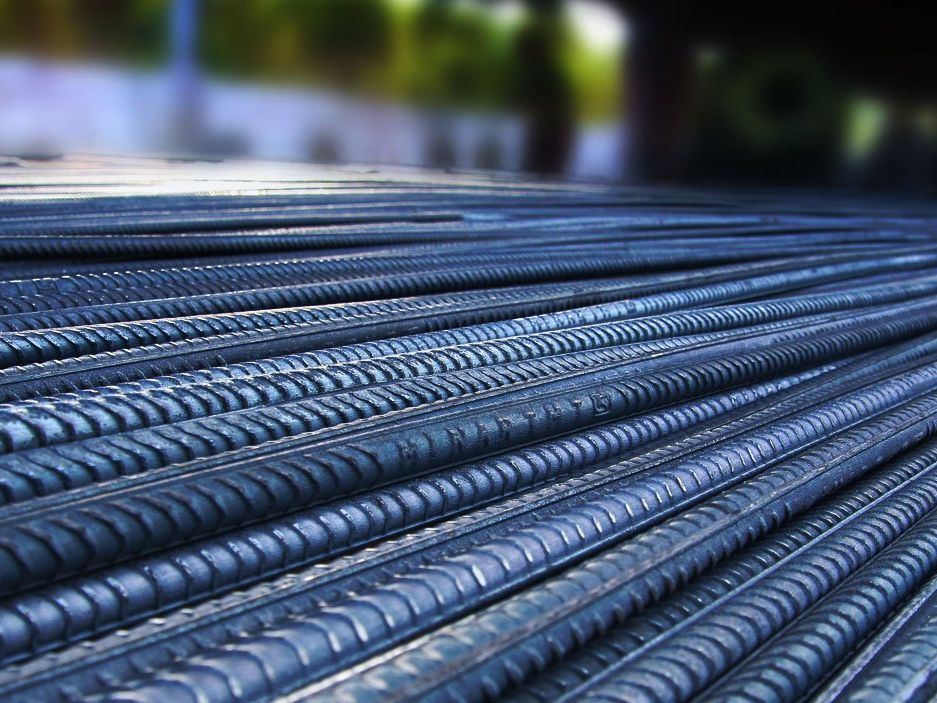

REINFORCEMENT

It is a specially shaped steel placed in concrete to meet shear and tensile stresses in reinforced concrete structures.

Iron is the most abundant metal in the earth’s crust. Although the liquid core at the center of the Earth is also predicted to be a single iron crystal, it is more likely to be an iron-nickel alloy. It is thought that such a high amount of dense iron mass at the center of the earth affects the earth’s magnetic field.

Direct reduced iron (DRI)

Direct reduced iron (DRI) is a type of metal substance produced by heating elemental iron in the presence of natural gas or gas produced from coal combustion.

Due to its low degree of oxygen, DRI is prone to oxidation and has a higher corrosion rate compared to other types of iron. Appropriate corrosion prevention methods must be used to prevent degradation of DRI in industrial applications. Further processing of DRI results in the formation of wrought iron and steel.

Directly reduced iron (DRI) reacts with reduced gases that are stripped of oxygen at temperatures below its melting point. The procedure results in a purer strain of iron that is free of impurities and fillers. DRI occurs in an environment heated to 1000°C–1200°C (1830°F–2190°F) in a chemically reducing atmosphere.

The following parameters can be changed to create variations in the type of DRI produced:

Oven type

Reducing fuel (coal or natural gas)

Iron ore input (piece, pellet)

IRON ORE CONCENTRATE

Iron ore concentrate contains between 66 – 69.5% Fe. Its main characteristic feature is that it contains low sulfur and phosphorus. It is used for pelletization in blast furnace.